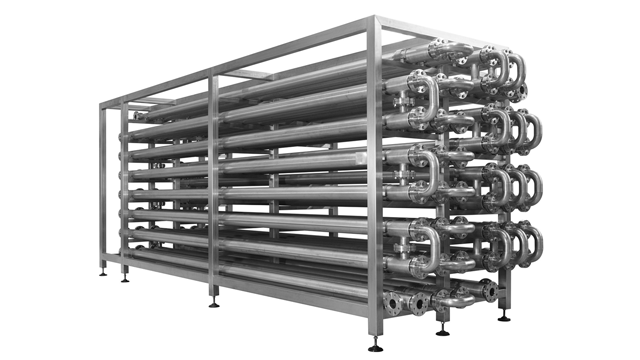

Tube-in-tube heat exchangers

Designed specifically for heating and cooling of sludge containing fibres and particles

The new Alfa Laval Tube-in-tube heat exchanger is specifically designed for sludge which contains fibres and particles, making it ideal for heating and cooling of most wastewater sludge. The equipment consists of a single tube mounted inside an outer shell tube, so that the product medium flows counter-current through the inner tube, with the service medium around it.

The unit features a fully welded construction with a bellow-on-shell tube to absorb thermal expansion. The Alfa Laval Tube-in-tube heat exchanger modules are typically connected in series and mounted on a frame. The shell tube is always smooth while the product tube is either corrugated or smooth depending on the application. The installation is maintenance free, thus eliminating any need for spare parts.

The layout of tube-in-tube heat exchangers can be customised to fit the available installation foot print or other customer requests.

How it works

The product medium inside the tube flows in counter current to the service medium. The product tube is corrugated, or it can be smooth. The shell tube is always smooth.

The range of Alfa Laval heat exchangers makes it possible to choose the optimum heat exchanger for each duty

Graphic representation of the flow pattern in the Alfa Laval Tube in Tube heat exchanger.

Services to extend your equipment performance

We support you with all types of services and training required for high performance and maximal ROI throughout the lifespan of your investment. With Alfa Laval as your service partner, you ensure reliable uptime and high efficiency while keeping total cost of ownership to a minimum.