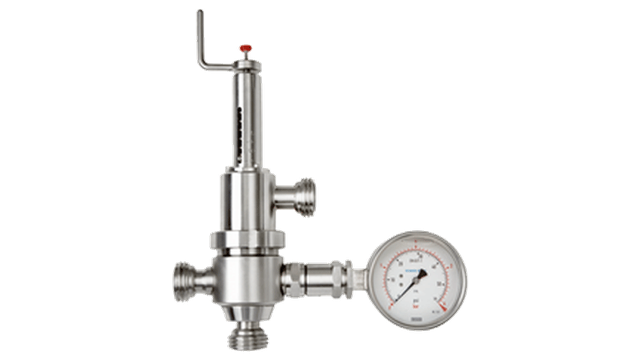

SB Tank Pressure Regulator

The Alfa Laval SB Tank Pressure Regulator maintains and regulates top pressure on pressure tanks during filling, processing and emptying. It usually connects directly to the gas/CIP pipe leading to the tank top or is incorporated into a flow panel. The regulator can be integrated with a SCANDI BREW® tank top system.

Secure tank top pressure control

Maintaining the working pressure at the tank top is critical. The tank pressure regulator makes sure that the pressure in the vapour space of a process tank is always at the optimal setting. This ensures the safety and effectiveness of your processes and safeguards product integrity.

Modular hygienic design

All pressure regulator components are made of high-quality hygienic materials that meet stringent food and beverage processing standards. Modular design provides the flexibility to meet most installation requirements. Hygiene is assured through the use of a CIP adaptor to provide full cleanability.

Product benefits

- Constant tank top pressure during filling, processing and emptying

- Reliable setting of working pressure

- Fully cleanable with CIP system

How it works

Construction

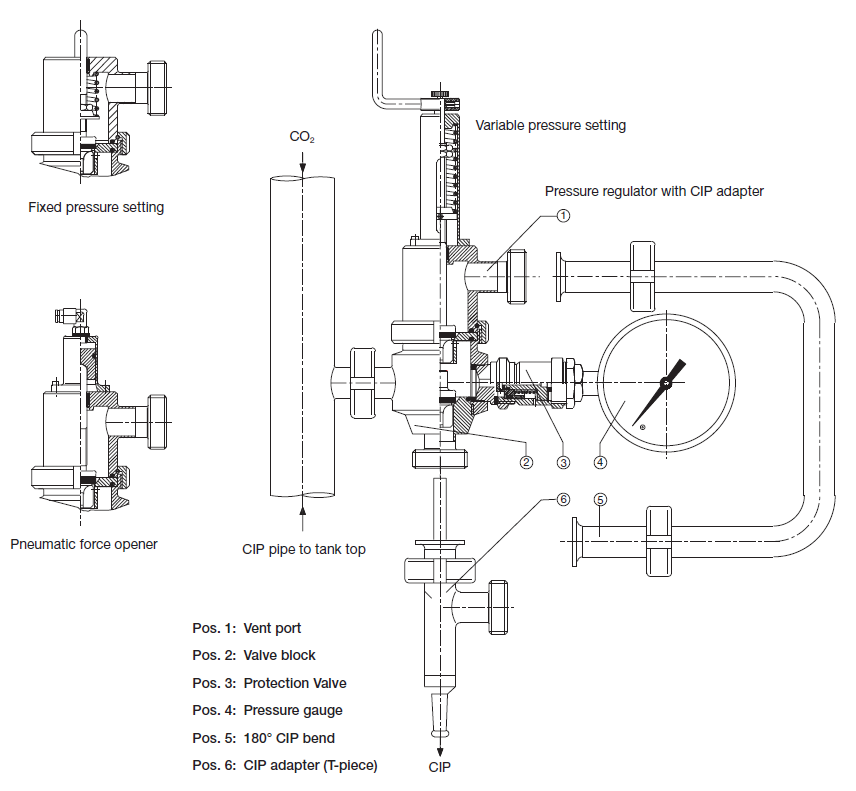

The tank pressure regulator consists of single valve unit incorporating a pressure exhaust valve, a pressure-supply valve and a connection for a pressure gauge. The pressure regulator can be supplied with a valve with different versions of the spring/regulating unit:

- Fixed setting (only one pressure)

- Variable setting

- Pneumatic actuator

The regulator can be integrated with a SCANDI BREW® tank top system.

Operating principle

The valve unit is supplied with either with a fixed setting or a variable setting, which adjusts the relieving pressure to the required working pressure in the tank. When tank top pressure exceeds the preset pressure, the regulator releases the gas through the vent port either for atmospheric discharge or for collection. If the tank top pressure decreases, gas is supplied through the gas supply connection at the bottom.

Cleaning-in-place (CIP)

The tank pressure regulator requires cleaning between every batch. It is incorporated into the tank CIP procedure by means of the optional CIP adaptor. Before cleaning, the CIP adaptor is mounted onto the pressure regulator; it forces open the gas supply valve and pressure relief valve and enables them to be fully cleaned. During the CIP procedure, all functions are blocked. See the schematic drawing of the regulator.

Options

- CIP adaptor (T-piece and 180°bend)

- Pressure gauge

- Protection valve for pressure gauge when CIP pressure exceeds range for pressure gauge

- Mounting brackets

- Force opener

- Mounting bracket on reverse side of valve block

Part of a broad valve range

Alfa Laval offers a comprehensive range of valves intended for hygienic applications in the dairy, food, beverage,home care, personal care, biotechnology and pharmaceuticals.

For a broader valve range, explorer the different product categories: ball valves, butterfly valves, control/check valves, diaphragm valves, double seal valves, double seat valves, safety valves, sample valves, shutter valves and single seat valves.

Ten top tips - Valves

Here are some tips and service videos to show how you keep your hygienic valves in tip top condition

Food Logic

Alfa Laval's hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients. Keeping up with the food industry trends and addressing four key challenges; supplying food products to consumers at a competitive price, getting the most from raw materials, reducing waste and emissions, and delivering safe and hygienic food products.

Product catalogue

Alfa Laval's hygienic equipment product catalogue "Close at hand" includes product leaflets, performance curves, links to animations, brochures and price lists for ordering purposes.

CAD portal

Download the product models in Neutral or Native CAD file formats. It is also possible to download 3D PDF files.

Animations

Visit the animations site and take a look inside a product to see and understand how it works.

Valves & Automation

near Newsletter

To keep you updated on important sustainability issues and opportunities in your industry and processes.