PureDry

Recover oil while reducing waste handling costs. Alfa Laval PureDry is an automated system that separates waste oil into three phases: cleaned oil, water and super-dry solids.

Automated and modular

- Processes continuously at flowrates of up to 300l/h

- Compact, modular system, install in any space

- Integrates with onboard systems

- Smart automation adapts process control to feed conditions

- No water consumption or additional waste generated

Substantial savings on waste oil handling

PureDry cuts the cost of waste oil and sludge handling by removing water from the waste oil and concentrating the solids to super-dry sludge (typically 15-25 kg/24 h), thus eliminating oily waste and related disposal costs.

The efficiency of the system in terms of drying up oily waste streams means holding tank volumes for waste oil and waste water can be reduced, thus freeing up valuable space on board a ship or in a power plant.

Furthermore, waste fuel recovery is possible when fuel oil sludge are separated from lube oil sludge (separate sludge tanks) – fuel saving typically up to 0,4 % is possible.

Reliable operation

The uniquely simple separator design ensures easy, reliable operation. The system separates the waste oil into three phases: cleaned oil, super-dry solids which can be disposed of as dry waste, and water clean enough to be sent to the bilge system. Smart automation adapts the process control to varying feed conditions. There is no water consumption and no additional waste generated.

Compact modular design

The compact PureDry system comprises a pumping module with emulsifier dosing unit, a heating module, a separation module and a control unit. Its modular design provides flexibility for installation in any convenient location and makes it easy to integrate with existing onboard systems.

Integrated waste oil/bilge water treatment concept

In combination with Alfa Laval’s PureBilge system, PureDry forms a complete, integrated sludge/bilge water treatment solution that can dry up all oily waste streams on the ship or in the power plant. PureDry separates out the oil, concentrates the solids to super-dry sludge which can be landed as dry waste, and sends the water to the bilge system. PureBilge then takes care of the fine polishing of the oily water prior to discharge overboard.

Alfa Laval's Adaptive Fuel Line

Alfa Laval’s Adaptive Fuel Line will provide engine protection and energy efficiency while keeping you in compliance with new regulations.

How it works

How it works

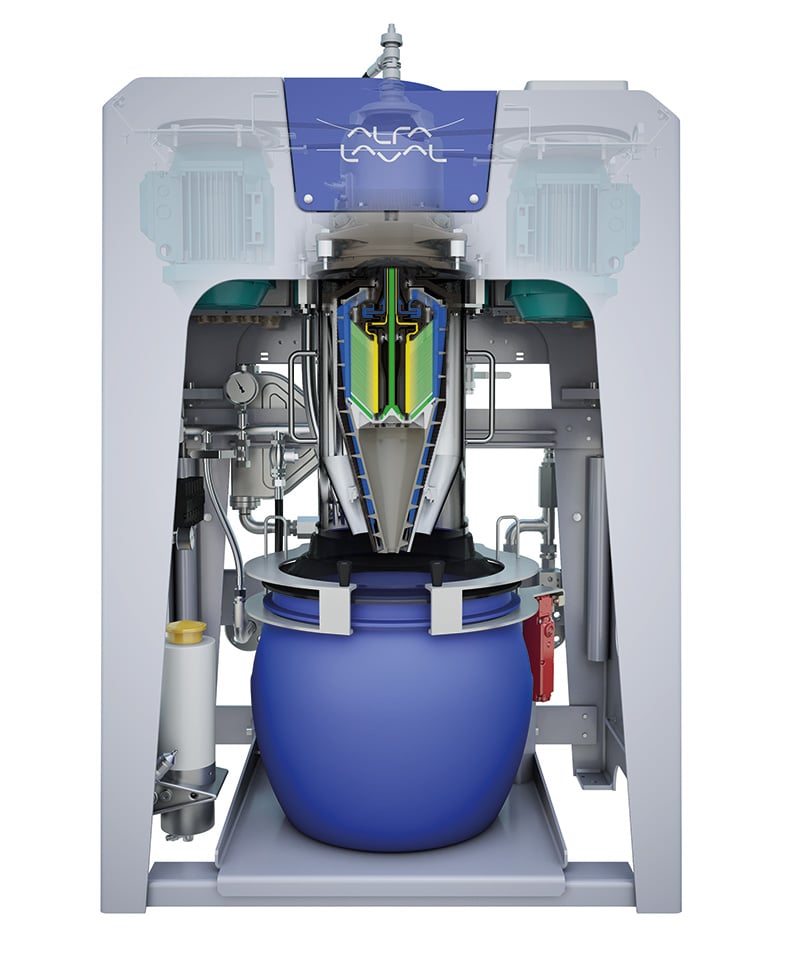

The PureDry system continuously processes oily waste. It has a pumping module with a dosing unit, a heating module, separator module and control unit.

A positive displacement feed pump directs the waste oil into the system. The process liquid passes through a duplex strainer and goes into the pre-heater. A three-way changeover valve directs the waste oil to the separation stage.

The separator bowl has a disc stack, an oil paring disc and a water paring disc. The disc stack rotates at high speed so solids accumulate at the bowl's periphery. Our patented XCavator device continuously discharges the solids into a container under the separator.

The oil paring disc continuously discharges recovered oil into the holding tank. The water paring disc discharges the separated water through the water outlet. It's then transferred either to the bilge water treatment system or back to the waste oil tank. You can combine PureDry with the Alfa Laval PureBilge system for an integrated waste oil/bilge water treatment solution.

The process is continuously monitored and controlled by the EPC 60 control system for automatic operation.

Maintenance and service by exchange

Your PureDry system comes with an exchange kit that includes a new separator insert, XCavator and consumables.

The XCavator and separator insert must be replaced after a year – it's as easy as replacing a filter insert so there's minimal downtime. Simply return your used parts to your nearest Alfa Laval Service Center and request new ones.