Marine semi-welded plate heat exchangers

Semi-welded plate heat exchangers are suitable for fuel conditioning duties involving alternative fuels, LPG cargo handling duties, refrigeration duties and Organic Rankine Cycle (ORC) duties. Our marine line features the unique Alfa Laval RefTight™ sealing system, which guarantees a long lifetime sealing between the welded channels because the laser weld is on the outside of the ring gasket groove. The smooth surface ensures a tight uniform seal over the entire gasket ring.

Highly efficient and flexible marine heat exchangers

- High efficiency that reduces energy consumption and OPEX

- Long service life, comparable to the vessel lifetime

- Serviceable without hot work, protecting uptime

- Easy maintenance on board through CIP or mechanical cleaning

- Extendable capacity through the addition of plates

Alfa Laval’s marine semi-welded plate heat exchangers are available for a broad range of temperatures and media, with operating pressures up to 65 bar. Robustly constructed, they provide exceptional longevity with their resistance to vibrations and pressure cycles. The various sizes, which cover a wide spectrum of heat transfer capacities and flows, are carefully designed and selected to achieve optimal performance. The cooling media/seawater side is fully accessible without disconnecting the semi-welded plate heat exchanger from the pipework.

Documents

Downloads

Instructions and manuals

Product brochures

Product leaflet

Applications

Heating and cooling in the engine room

On a ship, there are many types of machinery with a cooling demand. When the heat energy cannot be recovered or utilized, the total costs of transferring it away from the machinery should be kept to a minimum. Alfa Laval can ensure a cost-effective central cooling system through our portfolio of innovative plate heat exchangers. Our gasketed plate heat exchangers have unique features that reduce the running costs for engine room cooling – and contribute to sustainability.

Heating and cooling for LPG cargo handling

The transport of LPG requires tailored cargo handling systems. Alfa Laval marine semi-welded plate heat exchangers are the ideal choice for the cargo condenser, thanks to their very high efficiency, their small footprint and the ease of performing service on board. The robust units resist vibrations and pressure fatigue, and more plates can be added if faster loading rates are desired.

Heating and cooling for methanol

As the marine industry decarbonizes, interest in methanol is growing and the first methanol-fuelled vessels are beginning to appear. Methanol is a clean-burning liquid fuel that enables carbon-neutral operations if produced from green sources. Yet it poses heating and cooling challenges compared to conventional fuels. Alfa Laval has the heat exchanger solutions to ensure safe and efficient work with methanol on board.

Marine refrigeration

Refrigerants are common in the marine industry, from chilling and freezing the catch on fishing vessels to air conditioning on cruise ships. Yet the refrigerant types are changing rapidly. Chlorofluorocarbon (CFC) and hydrochlorofluorocarbon(HCFC) refrigerants have given way to hydrofluorocarbon (HFC) refrigerants, and now many shipowners are exploring natural refrigerants like CO2. Alfa Laval has the heat exchanger solutions and expertise to support natural refrigerant choices.

Services

Marine service network

Our dedicated Marine Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment.

How can we help you?

Please contact us for questions and service requests.

For marine emergency service, please call +46 4636 7700.

Higher pressures demand a higher standard

If your heating and cooling duties demand higher pressures, it’s time to demand a higher standard of technology. Discover total reliability and efficient thermal performance with the Alfa Laval marine line of semi-welded plate heat exchangers.

Highly efficient with unique sealing system

Alfa Laval marine semi-welded gasketed plate heat exchangers are suitable for liquids and gases incompatible with normal gaskets or at higher pressures. They are commonly used in refrigeration applications for evaporation and condensation.

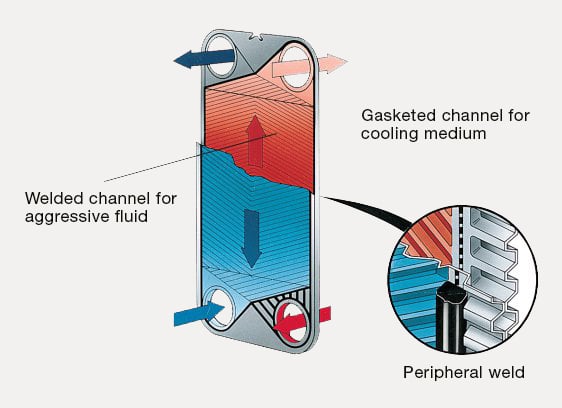

The unique Alfa Laval RefTight™ sealing system guarantees a long life-time sealing between the welded channels because the laser weld is on the outside of the ring gasket groove. The smooth surface ensures a tight uniform seal over the entire gasket ring.

What make our plate heat exchangers so reliable, efficient and serviceable?

Equipped with well-designed features that make a difference, Alfa Laval marine semi-welded plate line of heat exchangers are easy to maintain and have a long service life.

RefTight™

RefTight™

sealing system

High performance gasket sealing for high-pressure duties

CurveFlow™

CurveFlow™

distribution area

Improves media flow and minimizes risk of fouling.

OmegaPort™

OmegaPort™

noncircular port holes

Enhances media flow and thermal efficiency.

ClipGrip™

ClipGrip™

gasket attachment

Ensures perfect seal and trouble-free maintenance.

Five-point alignment

Five-point alignment

Ensures reliable plate positioning and easy service of large units.

T-bar roller

T-bar roller

Provides a lower unit that is easy to service.

How it works

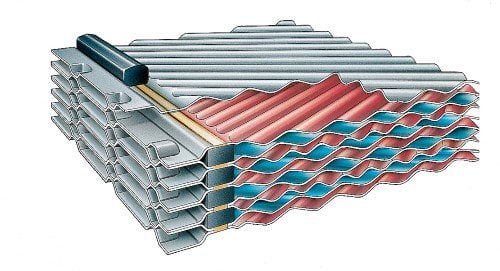

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

The sealing between the plates on the marine semi-welded line alternates between laser welds and gaskets. The laser welded channel allows use of fluids that are not compatible with normal gaskets and also allows for higher design pressure than fully gasketed plate-and-frame heat exchangers. Additionally, the Alfa Laval RefTight™ sealing system guarantees equal sealing force over the entire porthole gasket.

The marine semi-welded line is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are carefully designed and selected to achieve optimal performance. The CurveFlow™ and the chocolate pattern distribution area are two design features available that ensure fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

Liquid/Liquid GPHE

Steam Heater GPHE

>