Surimi processing

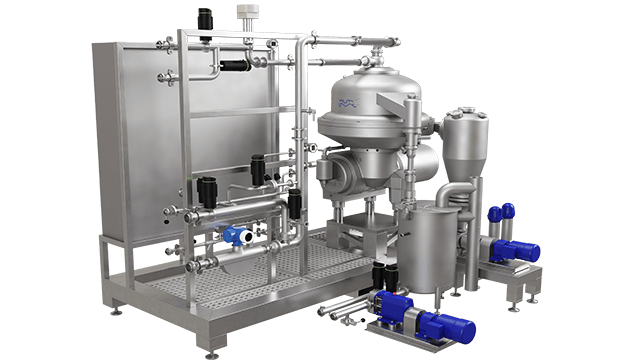

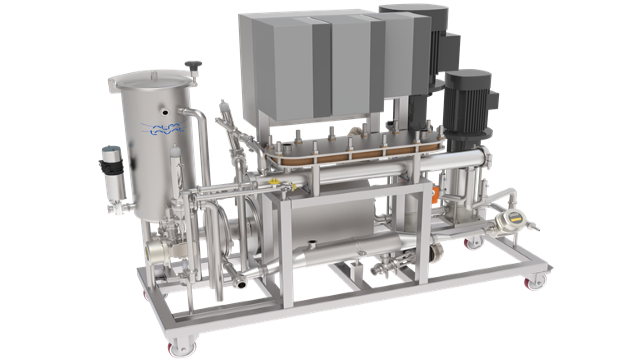

Alfa Laval’s decanter and separator solutions for surimi production enable higher process yield, better hygiene, and significantly higher product quality compared to traditional straining solutions.

Our equipment offers reliable operation under the toughest conditions and requires minimal installation space, making them ideal for both land and shipboard installations.

Whether you are planning an upgrade or building a new plant, contact our surimi experts to learn how we can help you maximize ROI.

Create high-value surimi from offcuts

Surimi plays an important part in the economics of fishery operations, offering a straightforward way to enhance the value of low-value fish species and optimize the utilization of raw materials within fish fillet production.

A surimi processing line is the perfect complement to a filleting facility. It allows you to create high-value surimi from offcuts and mince from the frames rather than downgrading it to animal feed.

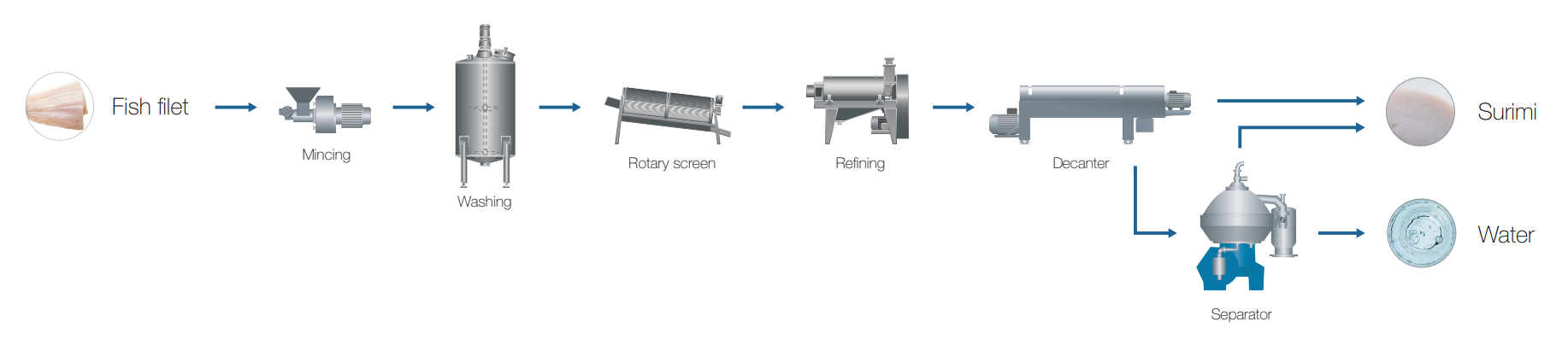

Surimi processing steps

The surimi production process washes out water-soluble elements, especially sarcoplasmic proteins and, in some cases, lipids from fish meat. The result is a functional fish product with a long shelf life, good gel strength, high binding capacity, and minimal flavour. The washed and dewatered fish mince is mixed with cryoprotectants – sorbitol and sugars before the product is plate frozen. The colour of the surimi depends on the fish species and typically ranges from greyish to white. The whiter surimi is most valuable as it is the easiest to add the desired colour to during the final processing, where it is layered, coloured and steamed to form the end product, e.g. crab stick.

Process description

- In the first stage of the process, any larger pieces of fish meat are minced and mechanically deboned to maximize the effectiveness of the subsequent washing step.

- Next, the fish mince is thoroughly washed in one or two stages and passes a rotary screen to remove as much of the sarcoplasmic protein as possible.

- Conventional, press-based systems include a second washing stage to ensure as much of the sarcoplasmic protein as possible is removed. In a decanter-based system, this second washing stage is omitted.

- Small residual amounts of skin, bones, and other unwanted materials are thereafter removed.

- In the next stage, the mince is dewatered, resulting in the final product.

- The wash water can be processed further in a separator to recover the smallest fines and maximize yield.

- In the last stage, the dewatered surimi is mixed with cryoprotectants (sugars and sorbitol) before freezing and packaging.

Upgrading the dewatering stage in a conventional surimi line by replacing the screw press with an Alfa Laval decanter brings several benefits. First, a decanter separates the meat from the wash water more efficiently, resulting in a significantly higher meat recovery. Second, only one washing step is required compared to at least two for a traditional screw press system, saving water and cost. Additionally, a decanter can be cleaned using CIP, as opposed to the manual disassembly required to clean a screw press. The result is better hygiene, shorter cleaning stops, and lower operating costs.

Decanter vs. screw press

Whether you are upgrading an existing surimi line or building a new plant, opting for a decanter offers several advantages over screw presses:

- Higher surimi quality thanks to more efficient removal of impurities

- Up to 50% higher yield due to better recovery of fines and fewer washing stages

- A much more compact system

- Significantly reduced water consumption, contributing to a more sustainable process and lower operating cost

- Easier operation

- More hygienic process with a much shorter retention time

- Better cleanability

Moreover, switching to decanters presents an excellent opportunity to expand capacity within an existing plant set-up.

Highly compact equipment, ideal for shipboard installations

Thanks to the compact nature of Alfa Laval decanters and separators, they require significantly smaller installation space than traditional screw presses. This, coupled with robust design and unmatched operational reliability, positions Alfa Laval decanters as the ideal choice for shipboard installations.

Quick and qualified service

With Alfa Laval as your trusted service partner, you can rely on prompt and qualified assistance whenever and wherever you need it, even in the most remote locations. Our global network of service offices provides professional support throughout all phases of your operations, including troubleshooting, regular maintenance, advanced performance audits, and predictive maintenance.

Utilizing our remote services, we provide instant assistance via digital channels. Our field technicians can be swiftly dispatched to any site or harbour worldwide if you need on-site support.

Our strong local network makes us the ideal service provider for companies with global operations, fostering closer cooperation and reducing administrative burdens. Put your trust in Alfa Laval for comprehensive service solutions, guaranteeing uninterrupted operations regardless of location.