Fish protein hydrolysates production

Hydrolysing protein from fish by-products yields a range of high-value products from 100% of your raw material while reducing your plant’s environmental impact. The high market price of hydrolysed protein makes hydrolysis a highly attractive alternative to traditional fish meal production.

Two different processes are used for hydrolysing fish protein: enzymatic hydrolysis and acid hydrolysis (silage). Alfa Laval offers complete processing solutions for both.

Transform low-value raw materials into high-value fish hydrolysates

Production of fish hydrolysates using side streams from fish filleting operations, such as fish heads, skin, bones, and viscera, produces high-value peptides and amino acids. The process also releases fish oil and other valuable nutrients from the raw material. The hydrolysis process causes the proteins to break down into water-soluble protein peptides with higher nutritional value and quality compared to traditional fish meal proteins.

The resulting protein hydrolysates can be used in sports nutrition, cosmetics, functional foods, and animal feed applications. Products include collagen supplements, refined protein peptide isolates, broths, fish sauces, and palatants for fish feed and pet food.

In addition, hydrolysing leftovers from fish processing reduces waste and offers a sustainable solution to the ongoing challenge of managing waste in the fish industry.

Enzymatic hydrolysis

Fish hydrolysates processing using enzymes is the preferred fish protein concentrate process for fish by-products from filleting operations. It is used to produce high-quality collagens and peptides, flavour ingredients for broth and fish sauces, and attractants for fish feed and pet food.

Two major benefits of enzymatic hydrolysis over acid hydrolysis are the higher quality of the resulting oil and protein and the possibility of finetuning the flavours and functionality of the final protein product by selecting different enzymes. Additionally, enzymatic processing enables the separation of the bones from the oil and protein, allowing producers to create calcium products that can be sold separately, thereby maximizing the total value.

Alfa Laval offers complete production lines for enzymatic hydrolysis, and our application experts are glad to support you throughout the entire process of designing and implementing a tailored solution optimized to your specific requirements.

Process description

- In the first stage of the process, the raw material is ground to improve enzyme action. The enzymes are added to the minced fish, and the mixture is heated to the optimal temperature for the chosen enzyme. If required, the pH level is adjusted to optimize digestion. For maximum control over the digestion process, the enzymes are added first when the hydrolysis is filled. This makes it easy to keep track of the digestion time and ensures all the raw material is processed for the same amount of time.

- The mixture is allowed to react for a specified duration, typically 1–3 hours, depending on factors such as the raw material, enzyme, and the required results.

- Once the desired degree of hydrolysis is achieved, the enzyme is inactivated through heating. The second heating stage also optimizes the temperature for the subsequent separation stage, ensuring maximum oil yield.

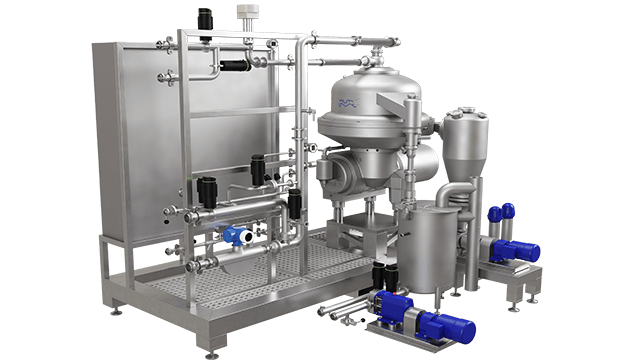

- In the separation stage, any undigested bone particles are removed before the slurry is processed in a separator or decanter, where the oil is separated from the protein. The choice of separation equipment depends on the concentration of the slurry. Separators are used for slurries with less than 5% solids and decanters when concentrations are higher. Since the hydrolysis process converts insoluble proteins into soluble proteins, more than 90% of the protein content resides in the water fraction exiting the separator or decanter. This fraction can be further processed in a membrane system using ultra- and nanofiltration to isolate specific peptides.

- Finally, the protein solution goes through an evaporation system and possibly a dryer, depending on the water-content requirements, to produce the final product.

Raw materials

- By-products from filleting operations

- Whole fish of smaller species that are not fit for direct human consumption

Silage processing (acid hydrolysis)

Producing fish silage from aquaculture stock mortalities, fish offcuts, and by-products like heads, skin, and viscera allows fish processing plants, fish farms, and fisheries to maximize raw material utilization and comply with increasingly stringent waste-discharge regulations. Fish silage is an ideal waste management solution for smaller fishing trawlers, fish farms, and fish processing plants where installing an enzymatic hydrolysis line is not possible.

Fish silage is produced by mixing the raw material with an acid. This is done at fish farms, on board fishing vessels or at fish filleting plants where the byproduct volumes are limited. Turning the by-products into silage means they can be collected and stored for up to six months before further processing, effectively reducing the seasonality in many operations. After processing the silage, the protein fraction can be used in fish feed and pet food, as a nutritional booster in biogas production, or as an organic fertilizer.

Alfa Laval offers complete system solutions for fish silage processing and protein extraction from fish. Our team of application specialists supports you throughout the entire process of designing and implementing a tailored solution optimized to your specific requirements.

Raw materials

- Fish offcuts and by-products

- Aquaculture stock mortalities (for use in fertilizer or biogas production, not as feed).

Process description

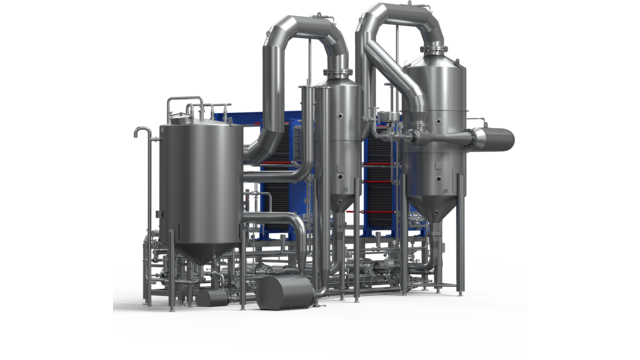

- In the first stage of the process, the raw material is minced and mixed with acid (usually formic acid or another organic acid) to lower the pH level to 3.5. This is typically done in small units with integrated tank and chopper pumps.

- After a few hours, the fish material is liquified, primarily due to the action of endogenous enzymes in the fish. The low pH level accelerates the breakdown and preserves the silage during storage. Thereafter, the mixture can be stored for several months before being collected and centrally processed.

- When the silage is received at the processing facility, it is screened to remove foreign matter such as plastic, wood chips and stones.

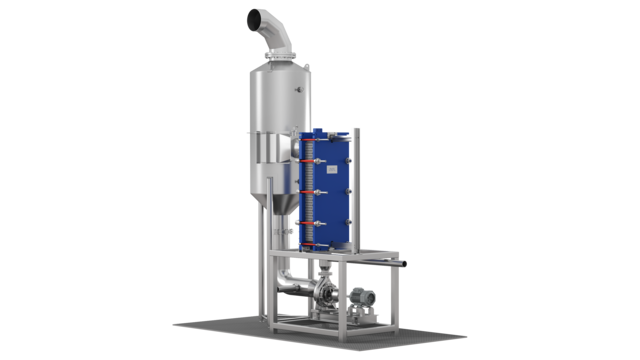

- Before the separation stage, the silage is heated to break up any fat emulsions and reduce the viscosity of the oil. This optimizes the conditions for the separation, ensuring maximum oil yield.

- In the separation stage, the oil is separated from the protein in a separator or decanter. The concentration of the slurry dictates the choice of separation equipment. For slurries with less than 5% suspended solids, separators are used, while decanters are utilized when concentrations are higher. The hydrolysis process converts insoluble proteins into soluble proteins, meaning more than 90% of the protein is in the water fraction exiting the separator or decanter.

- In the last stage, the protein solution is concentrated in an evaporation system or is dried in a drying system.

Raw material for biodiesel and HVO

The booming biodiesel and HVO markets have caused a strong growth in the demand for oils and fats. The oil produced in silage processing is unsuitable for human consumption but is an attractive raw material for biodiesel and HVO production.

In addition to silage processing lines, Alfa Laval offers complete raw material pre-treatment systems that remove phosphor, trace metals, chlorides, polyethylene, and other impurities.

Contact our experts to learn how you can take advantage of the opportunities in the biofuel sector.

Alfa Laval Foodec Oil Plus – setting a new standard for oil extraction

The new Alfa Laval Foodec Oil Plus is revolutionizing fish oil production. Thanks to its innovative design, Foodec Oil Plus extracts more oil than other solutions, ensuring maximal utilization of the raw material.

- Maximal oil yield due to special new decanter design

- Very pure oil, requiring minimal further processing

- Easy operation and maintenance

- Low total cost of ownership and short pay-back time – often less than 1 year

- Available as a plug-and-play skid

- Minimal change in your existing process, only one new component

Quick and qualified service

With Alfa Laval as your trusted service partner, you can rely on prompt and qualified assistance whenever and wherever you need it, even in the most remote locations. Our global network of service offices provides professional support throughout all phases of your operations, including troubleshooting, regular maintenance, advanced performance audits, and predictive maintenance.

Utilizing our remote services, we provide instant assistance via digital channels. Our field technicians can be swiftly dispatched to any site or harbour worldwide if you need on-site support.

Our strong local network makes us the ideal service provider for companies with global operations, fostering closer cooperation and reducing administrative burdens. Put your trust in Alfa Laval for comprehensive service solutions, guaranteeing uninterrupted operations regardless of location.