Hydrotreating

Stricter regulations for cleaner fuels challenge refineries to minimize contaminant levels through hydrotreatment processing. Optimized heat recovery is important to maximize process efficiency and throughput while severe process conditions place very high demands on equipment quality and reliability. Alfa Laval heat exchangers provide the highest operating performance in tough environments.

Optimizing hydrotreatment processes

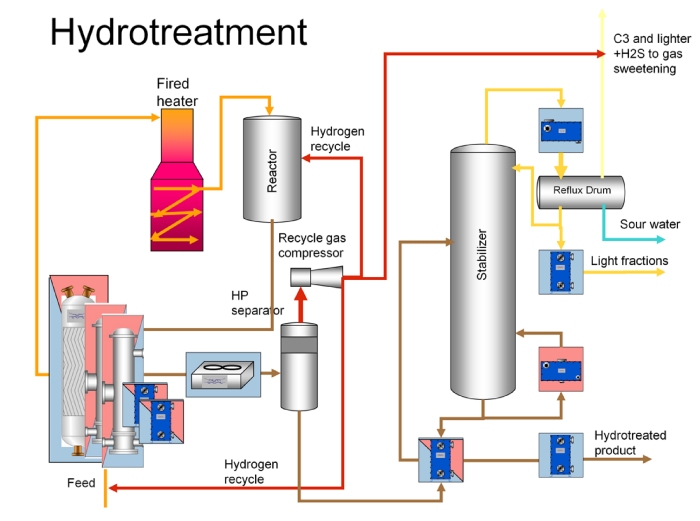

Hydrotreatment removes impurities from gasoline, jet fuel, diesel, and gas oil. The process consists of two sections: a high-temperature and high-pressure reaction section and a low-temperature product recovery section. Throughout the process, it is important to maximize energy efficiency, reliability and capacity while minimizing capital expenditures in order to boost the overall profitability of the refinery.

Energy efficiency

Reaction section

One of the most critical energy recovery positions in a refinery is the hydrotreater combined feed/effluent (CFE) interchanger. Here the hydrotreater feed is preheated by means of the reactor effluent. The closer the temperature approach, the less energy is required in the fired heater and the less cooling capacity of the effluent is required.

With a long temperature program and a tight temperature approach, this becomes an extremely large heat recovery service when using traditional shell-and-tube technology. It is not unusual to see up to eight shell-and-tube heat exchangers in series to maximize the energy recovery.

With high-efficiency plate technology such as Alfa Laval Compabloc or Packinox heat exchangers, it is possible to obtain maximum energy recovery using minimal space.

Single Packinox exchangers are designed with a hot approach temperature in the range of 12° to 30°C, compared to the typical hot approach temperatures ranging from 50° to 80°C for traditional shell-and-tube heat exchangers. In some cases, the fired heaters of the exothermic hydrotreatment processes are only required for plant start-up.

Product recovery section

Also, in the low-pressure section, maximizing process efficiency depends upon efficient energy recovery. To recover the maximum amount of energy using traditional technology, the installation of several large shell-and-tube heat exchangers for the stripper feed/bottoms is required. Using Alfa Laval Compabloc heat exchangers is an excellent alternative that maximizes energy efficiency while minimizing number of heat exchangers required as well as the plot space required.

Increasing reliability

Not only is the combined feed/effluent heat exchanger a very critical service in terms of maximizing process energy efficiency, it is also extremely critical in terms of process safety and reliability.

With the high hydrogen partial pressure and operating temperature of the fluids, these exchangers will operate under conditions where there is risk for high temperature hydrogen attack (HTHA) or hydrogen induced cracking (HIC) of carbon steel. This can result in the collapse of the metallic structure and, in the worst case, pose the risk of explosion.

Heat exchangers used in this service must be carefully designed to minimize the risk of HTHA or HIC failures. It is also critical to eliminate dead zones or crevices where hydrogen can be trapped and corrode the carbon steel base material. Whenever possible, be sure to prevent contact between carbon steel parts and the process fluids. Proper sealing to the environment is also a must.

Alfa Laval offers heat exchangers of all different types that are providing you with the highest quality and reliability possible.

Mitigating fouling in hydrotreatment processes

Fouling tendencies of the heat exchanger used in the combined feed/effluent service largely depend upon the process feed quality.

With light, straight-run naphtha, for instance, fouling tendencies are greatly reduced compared to when processing cracked naphtha from catalytic cracking, coking, hydrocracking, or other processes. Cracked naphtha contains olefins and di-olefins that polymerize and create gumming in the heat exchanger.

Another important parameter to consider is the oxygen content of the feed because oxygen promotes fouling tendencies. For process straight-run feeds, the oxygen content is normally low. However, if the feed comes from the tank, proper measures must be taken to minimize oxygen ingress into the feed during storage.

Finally, it is also important to minimize chloride and nitrogen content in the feed in order to limit the risk of salt formation in the exchanger.

To ensure heat exchangers with longest run-length and minimal maintenance requirements, it is important to know the conditions affecting the fouling tendencies and to select and properly design the most appropriate heat exchanger technology for the service.

Alfa Laval has a broad range of high-efficiency heat exchangers to meet virtually any operating condition at a refinery. Our Alfa Laval OLMI high-pressure, high-temperature shell-and-tube heat exchangers, Packinox and Compabloc exchangers are excellent choices for a wide range of combined feed/effluent heat transfer services. When processing cracked naphtha, for instance, our fully openable and mechanically cleanable Alfa Laval Compabloc heat exchangers are sound alternatives to other commonly used, hard-to-clean technologies.

Increasing capacity for hydrotreatment processes

Increasing capacity can be very expensive, especially when the capacity of the fired heater or hydrogen recycle compressor capacity is limited. High-efficiency Alfa Laval Compabloc and Packinox plate heat exchangers offload the fired heater and hydrogen recycle compressor by recovering the maximum amount of energy from the reactor effluent with minimal combined pressure drop. An increase of up to 30% in capacity can be realized without having to make any changes to the existing fired heater and compressor. In fact, the use of high-efficiency heat transfer technology reduces energy consumption per processed tonne of feed by 45%.

Minimizing CAPEX in hydrotreatment processes

To minimize the risk of HTHA or HIC, high-grade material is usually specified for the combined feed/effluent service, something which will make traditional shell-and-tube heat exchangers very expensive. Especially since so many of them will be needed for maximal energy efficiency.

High-efficiency Alfa Laval Compabloc and Packinox plate heat exchangers minimize the amount of heat transfer area required by at least a factor 3. This service only requires a single Alfa Laval Packinox exchanger and a maximum of two Alfa Laval Compabloc exchangers, which drastically reduces the total investment cost compared to shell-and-tubes. This is especially true when compact, lightweight Alfa Laval Compabloc exchangers are installed on construction as stripper or fractionator overhead vapour condensers.

Depending on the operating temperature and pressure, corrosiveness and fouling tendency of the service, Alfa Laval can select the best technology for your specific service from our wide range of heat exchangers and properly design it for maximal uptime.

Proven technology for hydrotreatment processes

Alfa Laval has a proven track record in delivering highly reliable, energy-efficient solutions for hydrotreatment processes at refineries around the world.

Alfa Laval has delivered 50 Packinox heat exchangers for combined feed/effluent interchanger service in hydrotreatment processes and several OLMI high-pressure, high-temperature shell-and-tube heat exchangers for that same service. In addition, Alfa Laval OLMI air coolers are typically used for reactor effluent cooling before the separator.

Refineries around the globe have more than 100 Alfa Laval Compabloc heat exchangers in use for various hydrotreatment services. These are used as stripper and fractionator feed/bottoms interchangers, overhead vapour condensers, column reboilers and fraction coolers. These are also used for combined feed/effluent interchanging service in naphtha and kero hydrotreating processes.